LEARN MORE

Pick and Place

The more the assembly/manufacturing line is in operation, the more pieces are produced. As demand increases, you may encounter production challenges like:

- Line speed increases to meet the demand

- May need to hire more workers

- Employee fatigue can become a factor

- Potential increase in errors

- Older equipment may breakdown or cannot handle an increase in production

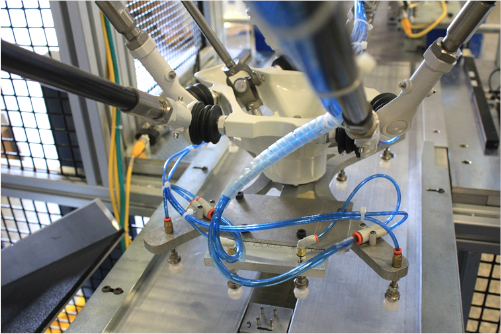

By taking a comprehensive approach to understanding the shape and complexity, a robotic pick and place can work with your assembly/manufacturing process. We can create a seamless integration that will:

- Utilize the appropriate EOA

- Incorporate proper vision hard and software

- Reduce overall per piece cost through automation

- Maximizing uptime to keep production goals met

We work across industries and focus on your specific process to design and implement a custom solution to fit your goals. Get a no-cost, hassle-free consultation from an experienced Flores Automation Project Manager or Engineer: 262-682-4229 or use our Quick Contact Form.